Maliaño, October 31, 2017. – Equipos Nucleares S.A, S.M.E. has received the approval of the MINETAD for the design of its ENUN 24P cask for the transportation of spent nuclear fuel. With this approval, the licensing process in Spain of the cask is concluded.

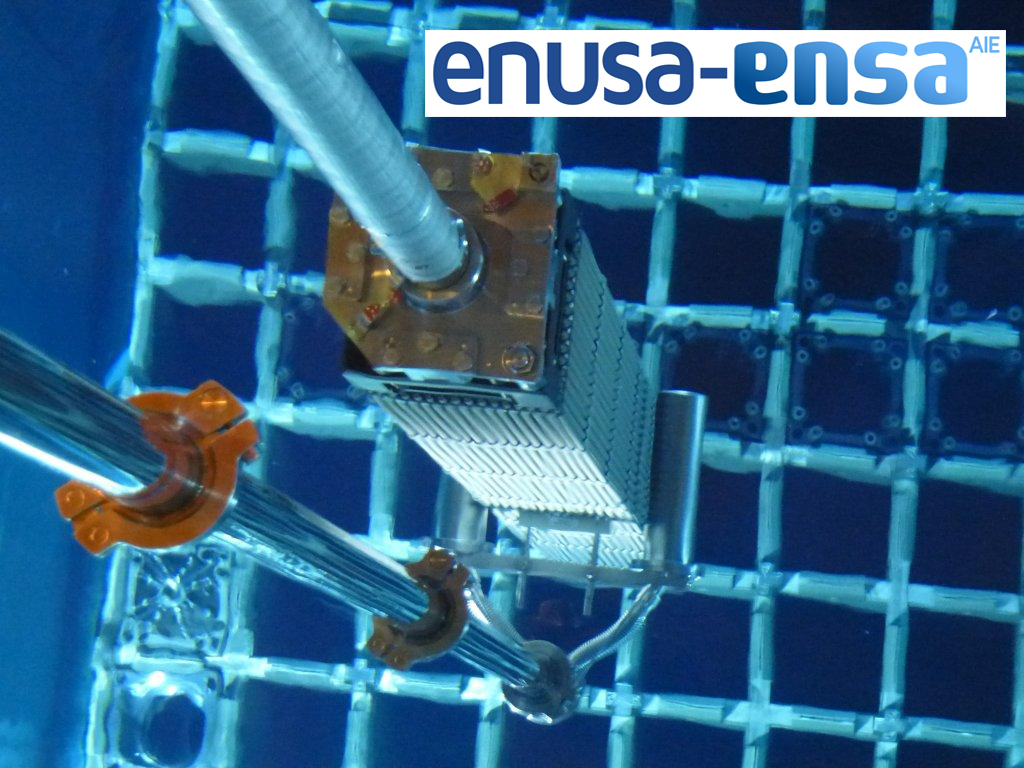

The design of the ENUN 24P allows the storage and transportation of up to 24 non-damaged used PWR fuel by road, rail and sea. Ensa has already manufactured a unit of this model, which has already been delivered to the Daya Bay plant in Shenzhen – China.

This license approval is a milestone for the Spanish nuclear industry, since the ENUN 24P is the first cask licensed in Spain that allows the transportation of high burnup fuel . Additionally, the ENUN 24P increases the list of self-designed casks already licensed by Ensa, adding to ENUN 32P and ENUN 52B.

The Energy Policy and Mines General Directorate of MINETAD, in accordance with the favorable report issued by the CSN and, as a result of the evaluations carried out, agreed to approve this design for «complying with the requirements for type B packages as per the regulations of the International Atomic Energy Agency and the Spanish regulations on the transport of dangerous materials «.

Ensa is currently providing support to its customer URC for the design validation process by the Chinese Nuclear Regulator Authority . This validation will presumably enable URC to carry out the first commercial high burnup fuel transportation in China.

Ensa belongs to the SEPI Group, a corporate holding company that comprises a total of 15 Spanish public companies directly and majority owned, with a workforce of almost 73,000 professionals. SEPI is also a shareholder of the Spanish Broadcasting Corporation , and has a public foundation and direct minority interests in nine other companies and indirect in more than one hundred companies.